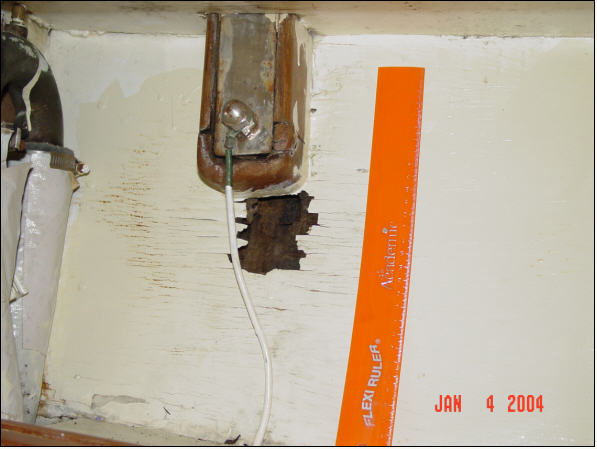

Extensive water damage caused by a leaking chainplate. The entire bulkhead in this 80’s vintage sailboat had to be replaced. Chainplates should be pulled, inspected, and re-bedded every 5 to 7 years (more frequently if leaks or other problems are noted).

Archives

Damaged Chainplate Bolts

Here are two good reasons why chainplates should be pulled and inspected (along with the bolts and other associated hardware) every 5 to 7 years – more often if leaking or other problems are noted. The upper bolt is noticeably bent, while the bottom one shows significant corrosion.

Horizontal Cracks in Swaged Fittings

“While vertical cracks in swaged fittings (typically a sign of internal corrosion) are bad enough, horizontal cracks indicate the need for IMMEDIATE corrective action. Such fittings have no safety margin (meaning they could fail at any moment) and must be replaced as soon as possible. As the rest of the rigging is probably the same … Read More

Leaky Chainplate

Chainplates should be pulled, inspected, and re-bedded on a regular basis, not only to avoid leaks and the associated headaches that go with them, but to inspect the chainplate itself for cracks and corrosion damage. Chainplates may look fine above and below the deck, but can have serious problems at the deck transition point.

Cracked Swage Fittings 1 & 2

Two good examples of problems associated with the deck level use of swaged fittings. “Swaging” is a process where tubular stainless steel fittings are essentially “crimped” onto rigging wire under high pressure. Salt water and other such corrosive elements run down the wire and migrate into the fitting, initiating rust, which in turn expands, eventually … Read More

Mast Corrosion

Severely pitted mast step